Superior Kiln-Dried Lumber

Why Buy From Us?

Minimum Order

Moisture Content

Process

Sorting

If you are a manufacturer of furniture, cabinetry, or other fine hardwood products, we have great news! You can now access the Stoltzfus Forest Products “stamp-of-quality” in kiln-dried lumber.

Stoltzfus Hardwoods

We distribute our kiln-dried lumber through Stoltzfus Hardwoods, our sister company. Visit the Stoltzfus Hardwoods website to learn more about our process and the lumber we sell.

Now You Can Have End-to-End Quality & Consistency – From the Forest to Your Facility

Now You Can Have End-to-End Quality & Consistency – From the Forest to Your Facility

Rest assured that your wood will be expertly handled from harvest to delivery, and that the optimum consistency and quality will be captured with the efficiencies of kiln drying right at the mill. We are excited to bring you the high level of quality control we pour into every step of our production up to this final stage, so crucial to high-quality hardwood lumber production.

Our Kilns

Our Kilns

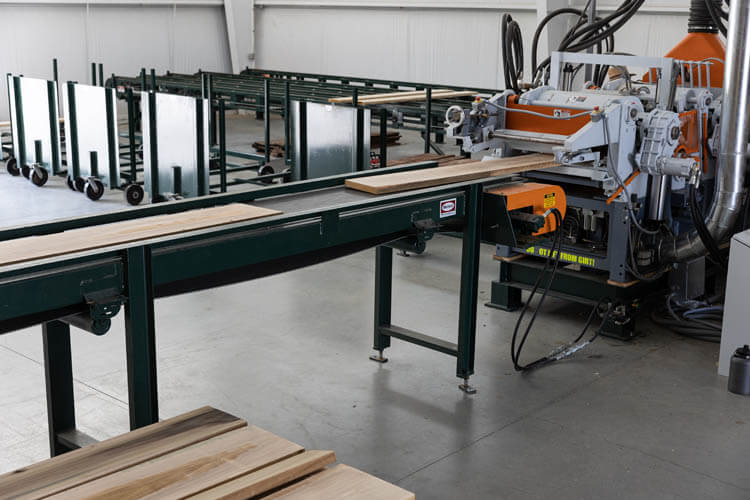

Our new SII kilns are built to produce! We have an initial production capacity of 130,000 board feet per batch. Using a special recipe of progressive heat and steam cycles, the moisture is coaxed out of the wood in a way that ensures minimal end checking or warping. Time in the kiln depends on the species and thickness. Each batch is carefully monitored, until it is brought to kiln-dried perfection. Our lumber is properly stress relieved, equalized, and conditioned, ready for you to craft into beautiful products.

Kiln-Dried Lumber Presents the Best of the Best

Kiln-Dried Lumber Presents the Best of the Best

Kiln drying offers a number of benefits in producing quality hardwood lumber. Insect larva and adults are sterilized from the heat process. Expertly dried lumber ensures boards that are typically straight and true. Wood quality and consistency is better than you can get from air-dried lumber.

Options to Put You at Maximum Efficiency

Options to Put You at Maximum Efficiency

Kiln-drying at our mill brings all kinds of exciting new options! Now you can have superior color match consistency, custom orders of separation by width and more!

– Choose from red oak, white oak, poplar, and walnut as kiln-dried lumber is offered in three grades: moulding grade, prime and 1 common. S2S (Surface Two Sides) planed lumber options are available as well.

– With a mere 500 board foot order minimum, we are the woodcrafter’s dream. It does not get much better than buying your lumber direct from the sawmill. And if you opt in for delivery, we will bring it right to your door.

Local Harvest, Local Craftsmanship

Local Harvest, Local Craftsmanship

We love local and we serve our community at both ends of the hardwood supply chain. Our harvest crew experts serve an eighty-mile radius of landowners with respect and dignity. Our kiln operators delight in producing superior hardwood lumber for the craftsman experts of our region. Our passion is serving up the winning combination for the success of local craftsmen and businesses!

Frequently Asked Questions

What is the optimum moisture content for the flooring, furniture & cabinet industries?

In North America most homes and offices range between 30 percent RH (Relative Humidity) and 50 percent RH. This equates to a range from 6.0 percent MC (moisture content) and 9.0 percent in the wood.

Manufacturing flooring, furniture and cabinets with wood that was dried to within the 6-9% MC range and maintained at that level throughout the shipping and manufacturing process will eliminate problems that would otherwise develop from using lumber with a higher moisture content.

Ideally you want to use lumber which is on the lower end of the scale as wood that absorbs a bit of moisture from its surroundings tends to cause less problems than wood that continues drying after it arrives in the consumer’s location. Wood products that are manufactured with a moisture content that is too high and then placed in an environment that continues to draw moisture out of the wood often results in cracking and splitting. For most of North America the closer you are to 6% MC the less problems your customer will have.

What are the pros and cons to drying wood below 6% MC?

In most cases manufacturing with wood that is dried below 6% MC is not advisable. One reason a manufacturer in the United States may want wood dried to below 6% MC would be if they are making cabinets or furniture to be exported to a very dry climate.

Generally speaking, wood that is below 6% MC should be avoided. There are a number of reasons you want to avoid wood that is dried below the optimum range:

- Additional costs to further lower the MC

- Brittle to the point of easily breaking

- Prone to cracking and splitting

- Gluing is challenging

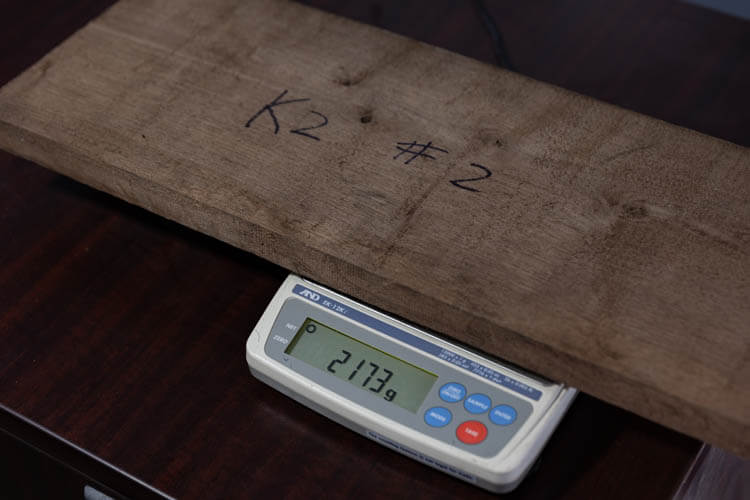

How much will the moisture content percent vary throughout my order?

We strive for a consistent moisture content percentage throughout each kiln dried lumber order we ship. There are factors that cause minimal fluctuation but MC range should consistently be between 6-8% with even less variation within the same species.

Is your kiln dried lumber color match sorted?

Stoltzfus Forest Products recognizes the need for color consistency in the flooring, furniture and cabinet industries, therefore we color sort our lumber so you have consistency throughout your order.

I am a small manufacturer, what is the minimum order amount?

We accept ½ bunk orders, which is 500 board feet, you can mix species and dimensions to reach the minimum.

Does the kiln drying process put undue stress on the lumber?

Any drying process puts stress on lumber, the key is to minimize stress and its consequences. In an attempt to produce the highest grade of dried lumber we operate 3 state-of-the-art SII kilns, which utilize both heat and steam cycles to minimize stress on the wood for minimal end checking and warping.

Why should a flooring manufacturer, furniture maker or cabinet shop buy Kiln Dried Lumber from Stoltzfus Forest Products?

- Higher quality lumber from our state of the art kilns.

- Consistent 6-8% moisture content.

- Low minimum order quantities are conducive to lean manufacturing.

- Color match sorting provides consistency throughout your order.

- Large in-stock inventory.

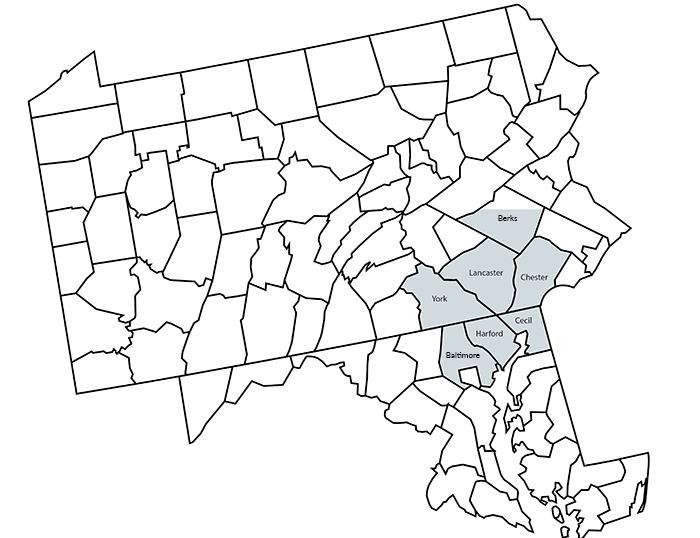

Our Kiln Dried Lumber Service Area

Our Kiln Dried Lumber Service Area

We ship our lumber in LTL quantities to the continental United States, with ½ bunk (500 board feet) delivery service to Delaware, Maryland, New Jersey, and Pennsylvania. Shipping is available worldwide for trailer load quantities.

Supplying cabinet shops, flooring manufacturers, and furniture makers with kiln dried oak, cherry, hickory, maple, poplar, and walnut from Lancaster, PA to Holmes County, OH and beyond. Our delivery area includes but is not limited to the following cities: Middletown, DE 19709, Wilmington, DE 19809, Hagerstown, MD 21740, Baltimore, MD 21230, Trenton, NJ 08601, Morristown, NJ 07960, Pittsburgh, PA 15106, Wilkes-Barre, PA 18701 and more.

Photo Gallery